Before it can be worked, the wood of choice has to respect a restricted range of humidity (10% to 14%). Only a company with large stocks of wood, and with a large drying capacity, can guarantee these parameters.

Raw wood is subject to natural adversities that cause cracks or branches. A careful selection prevents these defects from appearing in the final product. It is necessary to look for and reject any type of defect that may compromise the stability and durability of the product.

These triangular components - called corner-blocks - prevent the elements of a chair from splitting apart, providing the product with extra safety and many more years of use. The 2-slot system prevents it from moving around, and facilitates its application.

The tenon is a special component that allows the secure connection between two elements of a chair. Our tenons all have double striations, which prevent the glue being applied from depositing at the bottom of the perforation.

Our use of several CNC machines allows us to guarantee accuracy to the hundredth of a millimeter. This way we can always ensure that all chairs produced for a specific project are identical.

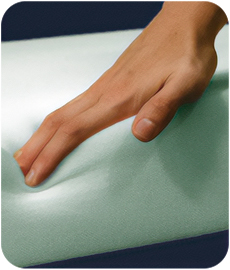

Only with the use of high quality foams can a homogeneous and comfortable finish be achieved throughout the chair. Space in the gaps must be adequate, neither too much nor too little.

Each of our chairs is always carefully inspected in order to detect possible imperfections. Depending on the severity, they can be corrected on the spot. We'll always guarantee the final product reaches its destination as intended.

Our testing machine takes each of our chairs to the limit, simulating a load of 100 kg on the seat and 30 kg on the backrest. Tens of thousands of repetitions are performed to ensure that our products can withstand intensive use.

We are an ISO 9001 certified company since 2013.